Water Resistant Watches.

Most modern watches are water resistant to some degree. This does not mean water proof. It means they will resist water ingress up to a certain degree, and watches are assigned a 'depth' rating according to their intended use. These ratings are not meant to be taken literally, but they do give you an idea of intended use. The lower the rating, the less robust the watch.

Water Resistance does not last indefinitely. Seals degrade, and case components can get damaged over time. When we open a case to change a battery, it is quite easy for the seal to get damaged and lose its ability to prevent water ingress. That is why we frequently replace worn or damaged seals and offer water resistance tests.

Example: Tissot PR50

This is a Tissot PR50 watch, probably about 10 years old. It came in for a battery and water resistance test. A quick inspection showed that the glass gasket was cracked. This happens after long exposure to UV light and compromises the watch.

See how dirt builds up around the case back. This should be cleaned off before the watch is opened. Otherwise it tends to end up inside the case and eventually work its way into the movement. Not everyone you take your watch to will bother with this step. Often there is no real attempt to clean this dirt away even before re-fitting the back.

Here I am driving the worn out case tube out of the side of the case with a special tool of my own making. The case tube has worn over the years and the watch has been leaking slightly through the crown (winder).

Now the watch case is stripped down to its component parts. The glass gasket came out of the watch in two pieces. The steel washer that holds the rubber o-ring in the crown has fallen out and the crown is bent.

This watch needs a new glass gasket, crown, setting stem, and case tube. Tissot makes a kit with all the parts required to bring the watch back up to standard.

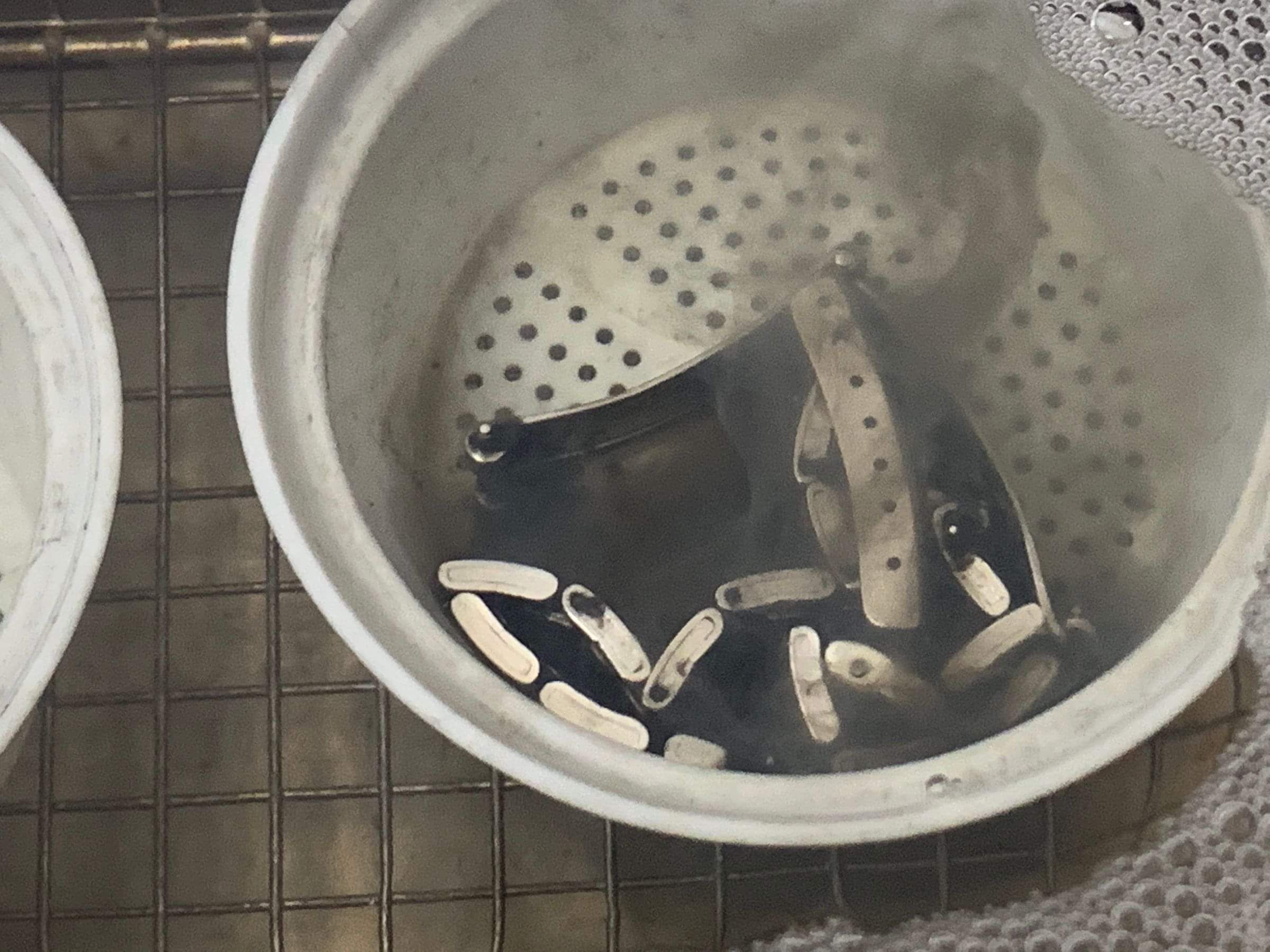

But first the case and bracelet need cleaning, so they go into the ultrasonic tank for a deep clean.

The bracelet needs some extra time in the ultrasonic to remove the dirt from inside the links, so while that continues cleaning I set to work on the case.

The case tube is glued into the case with high strength loc-tite, and the glass gasket is carefully fitted into the case and the glass pressed in. Then the movement is refitted with a new battery, and the stem is cut to length and screwed into the crown. Finally the case back is pressed into place. The case is now ready for pressure testing.

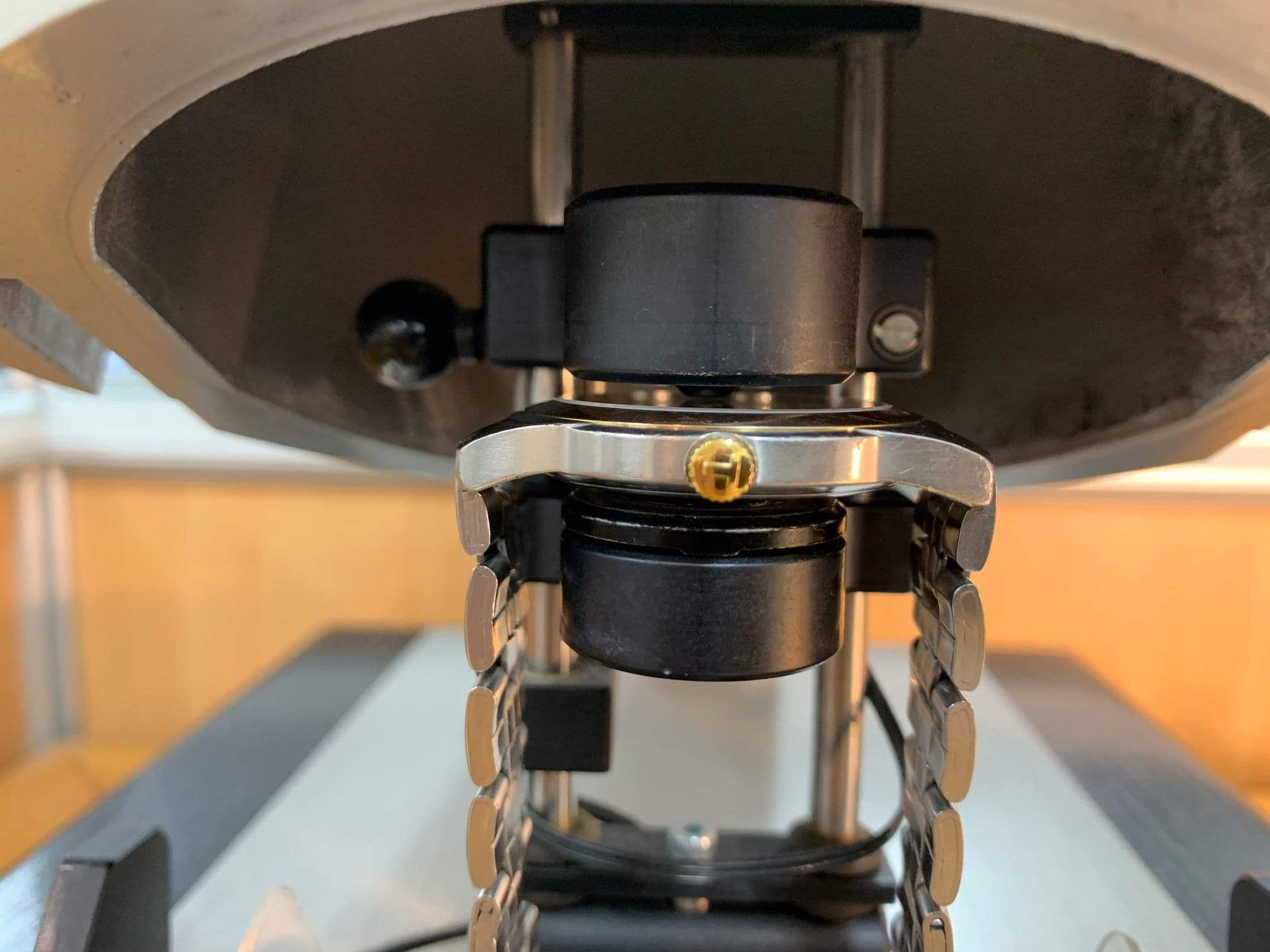

Pressure testing is done in an automatic air pressure tester. A sensor rests on the glass and measures the deflection under load. The first test is a vacuum, and the glass should flex outwards. Then air is pumped into the chamber to the desired pressure and the glass should flex inwards. If the glass fails to flex, then there is equal pressure inside and outside the case indicating a leak.